Air filters are the core component for ensuring clean air, widely used in environments from industrial spraying, electronics and pharmaceutical plants to hospitals and airports. However, in practice, many users have misconceptions about filter selection and maintenance. This not only fails to achieve the desired purification effect but also leads to increased operating costs and potential equipment damage.

As a company specializing in the R&D, manufacturing, and sales of air filters, Guangdong Haibei Purification Technology Co., Ltd. (Haibei Jing) draws on its extensive industry experience to analyze the three most common misconceptions in air filter usage.

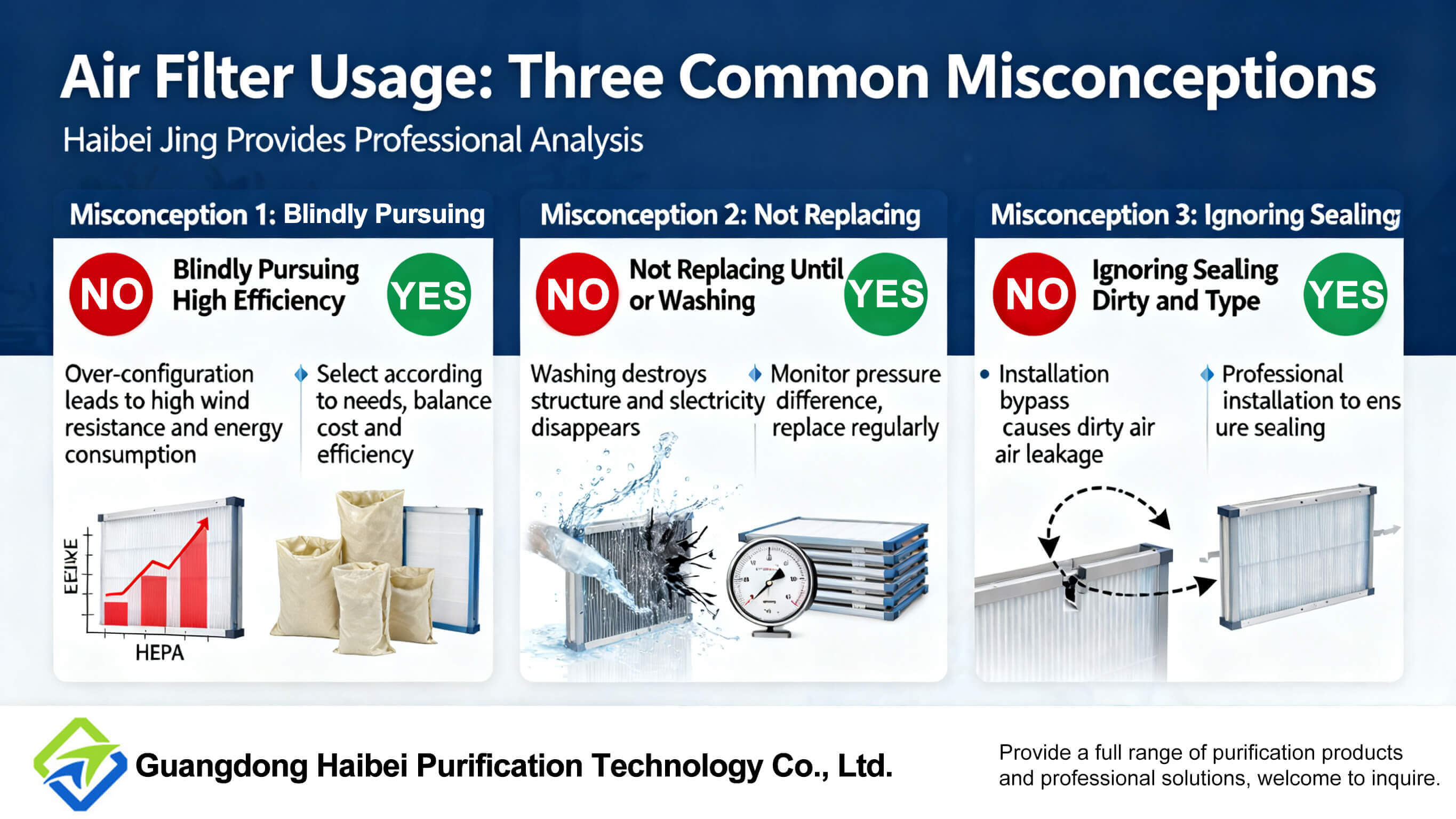

Misconception 1: Blindly Pursuing High Efficiency ("HEPA is Always Better")

Many users believe that the higher the filter's efficiency rating, the better. This leads them to choose HEPA (High-Efficiency Particulate Air) filters for all applications.

Haibei Purification Analysis: This is a classic "over-engineering" mistake. A filter's efficiency is directly proportional to its air resistance (also known as pressure drop). While a HEPA filter (e.g., H13 grade) can achieve an extremely high particle capture rate, its air resistance is far greater than that of a primary (pre-filter) or medium-efficiency filter.

1. Increased Energy Consumption: High air resistance forces the air conditioning or purification system (like an FFU) to run its fan at a higher power, causing a sharp increase in energy consumption.

2. Reduced Airflow: If the system's fan is not powerful enough to overcome the high resistance, the actual airflow will be much lower than designed. This reduces the overall air change rate, leading to poor purification.

3. Shortened Lifespan: Operating under a high load accelerates fan aging and causes the HEPA filter to reach its final resistance (end-of-life) much faster, shortening its replacement cycle.

Haibei's Recommendation: Filter selection should be "site-specific." For example, HEPA is necessary for locations with extremely high cleanliness requirements, such as semiconductor or microelectronics manufacturing. However, for most commercial buildings, automotive plants, or as a pre-filter for a larger system, using a Haibei Jing Medium-Efficiency Bag Filter or Pleated Medium-Efficiency Filter provides the best balance of energy consumption and cost while ensuring adequate cleanliness.

Misconception 2: Not Replacing it Unless It's Visibly Dirty (Or "Reusing Filters After Washing/Vacuuming")

To save costs, some users wait until the filter surface is visibly black before replacing it. Others may even try to "clean" the filter by washing it with water or vacuuming it.

Haibei Purification Analysis: This practice is completely wrong. Air filtration relies on five key mechanisms, especially the Diffusion Effect (for small particles) and the Electrostatic Effect.

1. "Dirty" is More Than Surface Deep: A filter becomes clogged primarily by microscopic particles (like PM2.5) filling the gaps between its fibers, which are invisible to the naked eye. By the time you see the filter turn black, its internal structure is already saturated, and its air resistance is excessive.

2. Washing Destroys the Structure: The filter media in most medium- and high-efficiency filters (made of non-woven fabric or fiberglass) is severely damaged by washing. The fiber pores enlarge, causing the filtration efficiency to plummet.

3. Electrostatic Charge is Lost: Many filter media, such as Haibei Jing's Electrostatic Cotton Filters, rely on a static charge to capture fine particles. Washing or excessive patting will permanently neutralize this charge, rendering the filter almost useless against sub-micron particles.

Haibei's Recommendation: You must strictly follow the recommended replacement schedule or use a differential pressure gauge to monitor the pressure drop across the filter. When the resistance reaches its "final resistance" value—even if the filter looks clean—it must be replaced immediately. This is the only correct way to guarantee purification performance and protect downstream equipment (like fans and HEPA filters).

Misconception 3: Focusing Only on Dimensions, While Ignoring "Sealing" and "Filter Type"

When replacing a filter, users often only pay attention to the length, width, and height, assuming that as long as it "fits" in the slot, it will work.

Haibei Purification Analysis: The "seal" is the most critical part of a filter's installation. Even a tiny 0.1% gap (known as "bypass" or "leakage") can cause the entire purification system's efficiency to drop by 30% or even 50%.

1. Bypass: Air will always take the path of least resistance. If there is a gap between the filter frame and the mounting housing, a large volume of unfiltered "dirty" air will simply flow around the filter, quickly contaminating the downstream HEPA filter or the cleanroom itself.

2. Mismatched Type: This is a failure to consider the filter's specific function. For example, if you need to remove odors and VOCs (Volatile Organic Compounds), you must use an Activated Carbon Filter. If you only install a HEPA filter (which targets particles), it will have no effect on chemical gases and smells.

Haibei's Recommendation: During installation, you must ensure the gasket is compressed uniformly and that there are no leaks. All filter products provided by Haibei Purification, from our Panel Filters to our Combined HEPA Filters, are equipped with high-quality sealing strips. Furthermore, before purchasing, be clear about your purification goal: Are you removing dust, germs, or odors?

Conclusion

Air filtration is a systematic process. Using and maintaining filters correctly is just as important as selecting a high-quality product.

Guangdong Haibei Purification Technology Co., Ltd. (Haibei Jing), as a purification equipment supplier with its own brand and professional production facilities, not only provides a full range of products—from Primary Nylon Mesh Filters and Medium-Efficiency Bag Filters to HEPA Filters, FFUs, and Air Showers—but is also committed to providing customers with professional purification solutions.

We adhere to our mission of "Quality Assurance, Integrity in Transactions, Reasonable Pricing, and Service First," with products exported to many countries in Europe, the Americas, and Southeast Asia. If you encounter any challenges in selecting or using air filters, you are welcome to contact us for an inquiry.

Explore our full range of air filters and find the perfect solution for your needs. If you need assistance purchasing filters or confirming filter size, please call +1 929-204-8922 (9-5 EST Monday-Friday) or email info@gdhaibei.com.