High-temperature high-efficiency filters, including high temperature HEPA filters, are engineered to remove particulate matter from airstreams in elevated temperature environments, while maintaining functionality and structural integrity. Constructed with specialized materials like stainless steel frames and glass fiber filter paper, these filters can withstand temperatures up to 250°C~350°C. They are widely utilized in industrial and manufacturing processes, such as clean ovens, depyrogenation tunnels, and drying processes within the pharmaceutical and food & beverage industries, as well as in high-temperature purification sites like the spraying, chemical, and ultrasonic industries.

Heat Resistance:

They are constructed with materials that can withstand high temperatures, ranging from 250°C to 350°C (482-662°F) or even higher in some cases.

High Efficiency:

They typically meet HEPA filter standards, meaning they can remove at least 99.97% of airborne particles 0.3 microns in size and larger.

Specialized Applications:

They are essential for processes that involve sterilization, depyrogenation (removal of pyrogens or fever-inducing substances), and other high-temperature purification steps.

Reduced Particle Generation:

Some designs prioritize low particle generation at high temperatures to avoid contamination of the treated materials.

No Silicone Use:

Some high-temperature HEPA filters are manufactured without silicone to prevent contamination of sensitive products, like those in the pharmaceutical industry.

Various Sizes and Configurations:

These filters come in different sizes and configurations, including box-type and other specialized designs to fit various applications.

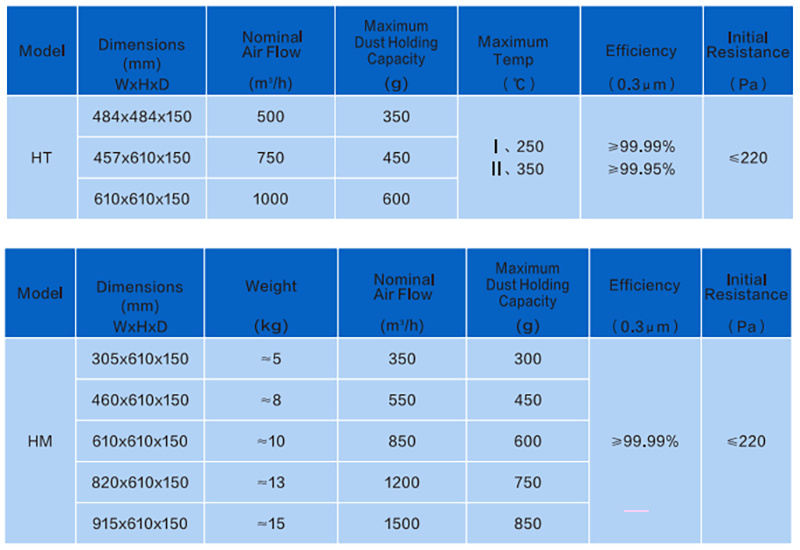

Specifications:

High-Temp High-Efficiency Filter Applications:

Depyrogenation tunnels:

These tunnels use high temperatures to eliminate pyrogens from pharmaceutical products, and high-temperature HEPA filters are crucial for maintaining a sterile environment.

Clean ovens:

These ovens, used for drying or heat treatment processes, require HEPA filtration to remove contaminants and ensure product purity.

Drying processes:

In various industries, high-temperature HEPA filters are used in drying processes to prevent contamination from airborne particles.

Pharmaceutical manufacturing:

High-temperature HEPA filters are essential for maintaining sterile conditions during various manufacturing steps in the pharmaceutical industry.

Installation and Usage:

Do not use any sharp objects to touch the fragile glass filter. Do not touch the glass filter material with your hand while carrying the filter.

During usage, do not raise the temperature above 250°C in a short time directly. The best way to increase the temperature is to add 50°C per hour. Finally stabilized to between 200°C and 350°C. In order to ensure the service life, it is necessary to add a primary filter, glass fiber primary air filter can be used to collect large particles of dust to enlarge high temperature HEPA filter service life.

Filter Customization:

Explore our full range of air filters and find the perfect solution for your needs. Please send us your requirements to get custom sizes and thicknesses.