In spray painting operations, the emission of exhaust gases containing paint mist particles poses significant environmental and health risks. Without proper treatment, these pollutants can violate regulatory standards and harm workplace safety. This guide explores how paint mist filter cotton and glass fiber cotton serve as effective solutions for spray booth exhaust purification, ensuring compliance and operational efficiency.

Understanding Paint Mist Filter Cotton & Glass Fiber Cotton

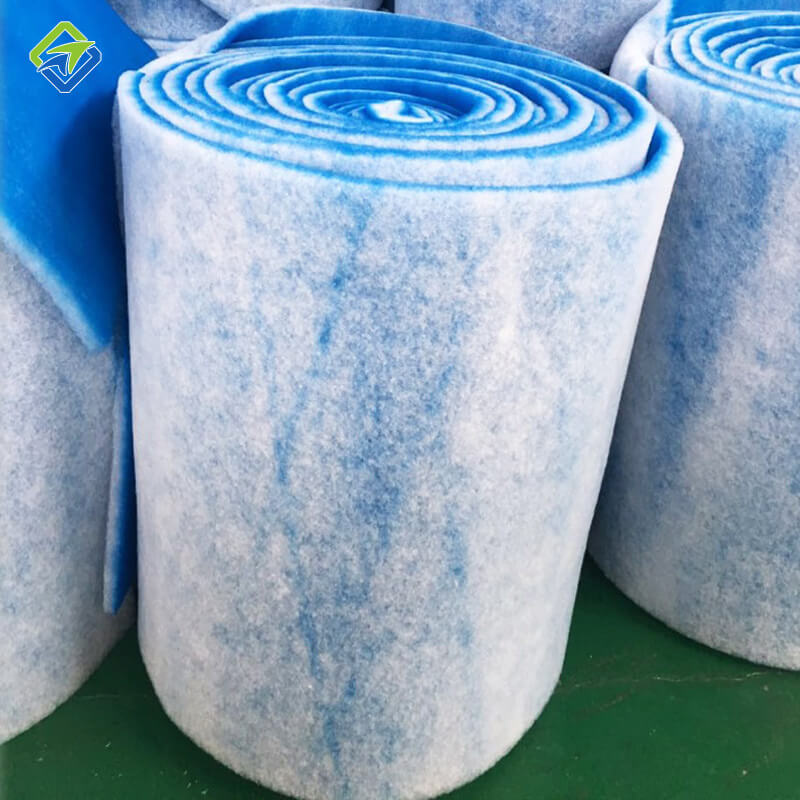

Paint Mist Filter CottonPaint mist filter cotton is engineered with a porous polyester fiber structure designed to capture liquid and solid paint particles. Its key features include: - High dust-holding capacity, making it ideal for extended use in spray environments. - Low airflow resistance, ensuring smooth airflow in the spray booth. - Fluffy texture, providing maximum surface area for adsorption. - Lightweight design, allowing for easy replacement and cost-effective maintenance.

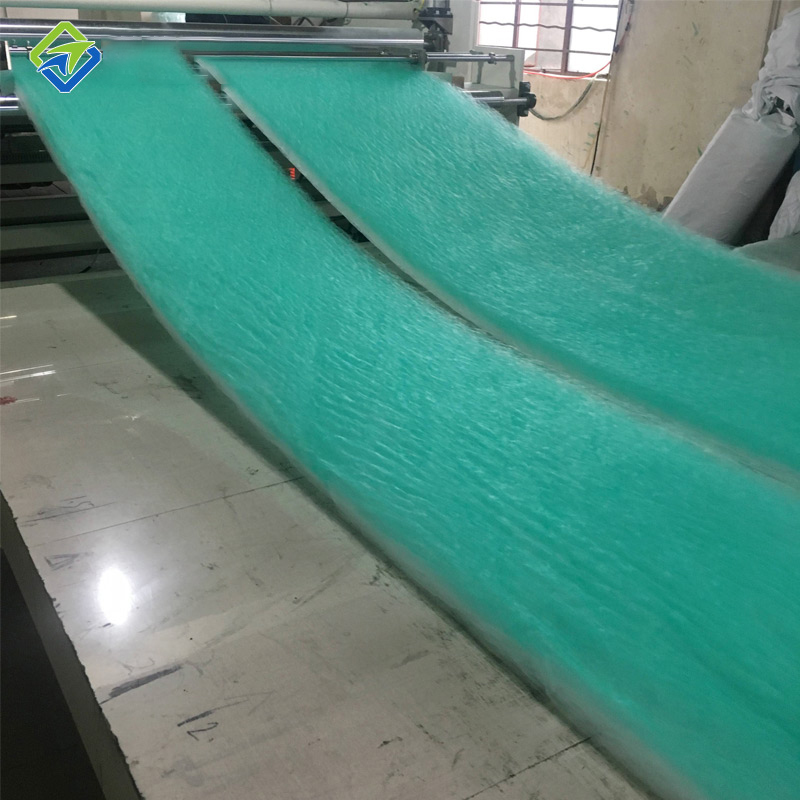

Glass fiber cotton offers advanced filtration performance through its fine, uniformly distributed glass fiber composition. Its advantages are as follows: - Excels in high-temperature and corrosive environments, suitable for industrial-grade applications. - Superior particle retention capabilities, especially for sub-micron paint droplets. - Excellent chemical stability, ensuring consistent filtration efficiency even under harsh operating conditions.

Critical Roles in Commercial & Industrial Spray Painting

Commercial Spray Painting ScenariosIn commercial settings such as auto body repair shops and furniture finishing facilities, maintaining product quality and workplace hygiene is paramount. Paint mist filter cotton prevents overspray from contaminating finished surfaces, reducing rework rates and material waste. When paired with glass fiber cotton, these solutions create cleaner workspaces that: - Comply with occupational health regulations. - Enhance employee productivity and satisfaction.Industrial Spray Painting OperationsFor industrial operations like automotive manufacturing plants and heavy machinery coating lines, high-volume paint application generates concentrated mist levels requiring robust filtration. The combination of paint mist filter cotton and glass fiber cotton forms a multi-stage filtration system: - Paint mist filter cotton: Responsible for primary large particle capture. - Glass fiber cotton: Handles secondary fine particle removal. This setup ensures: - Compliance with strict environmental standards. - Minimization of the risk of regulatory penalties. - Protection of downstream equipment from paint residue buildup.

How Paint Mist Cotton Filters Paint Effectively?The filtration mechanism of paint mist cotton relies on a combination of adsorption, inertial impaction, and interception. As contaminated airflow passes through the material:

- Paint droplets adhere to the fiber matrix. - Solid particles are trapped by the material's dense structure. This dual-action process prevents paint particles from reaching exhaust stacks or damaging sensitive equipment like activated carbon filters and fans.

Key Applications

- Automotive production lines: Installed in spray booth intake/outtake systems to protect precision painting equipment. - Furniture manufacturing: Reduces overspray contamination on wood and metal surfaces. - Industrial coating facilities: Extends the lifespan of HVAC systems and exhaust treatment units. - Consumer goods production: Ensures consistent finish quality for toys, appliances, and electronics.

Why Choose These Filtration Solutions?

Both filter materials offer distinct advantages for spray booth operations:

- Cost-efficiency**: Long service life reduces replacement frequency and operational downtime.

- Regulatory compliance**: Meets international standards for volatile organic compound (VOC) and particulate matter emissions.

- Versatility**: Adaptable to various paint types including water-based, solvent-based, and powder coatings.

- Equipment protection**: Prevents paint buildup in ventilation systems, reducing maintenance costs.

By integrating paint mist filter cotton and glass fiber cotton into your spray booth design, you create a sustainable filtration strategy that balances performance, compliance, and cost-effectiveness. These materials not only address immediate exhaust treatment needs but also contribute to long-term operational success in competitive manufacturing and finishing industries.

Explore our full range of air filters and find the perfect solution for your needs. If you need assistance purchasing filters or confirming filter size, please call +1 929-204-8922 (9-5 EST Monday-Friday) or email info@gdhaibei.com.