Introduction

Choosing the right air filter media is crucial for HVAC efficiency and industrial safety. Here is a breakdown of the four most common filtration materials used today.

1. Non-woven Filter Cotton (Traditional & Cost-Effective)

Non-woven filter cotton is one of the earliest and most established filtration materials. Known for its mature technology and low production cost, it remains a staple in the industry. Recent advancements in composite non-woven technology have significantly upgraded its performance, shedding its former "low-end" image to achieve sub-HEPA efficiency levels.

Key Features: High stability, widely used, mature technology.

Applications: Typical material for primary (G-class) and medium (F-class) efficiency plate and bag filters.

Advantages: Compared to similar materials, it offers stable quality, high dust holding capacity, strong moisture resistance, long service life, and excellent economic value.

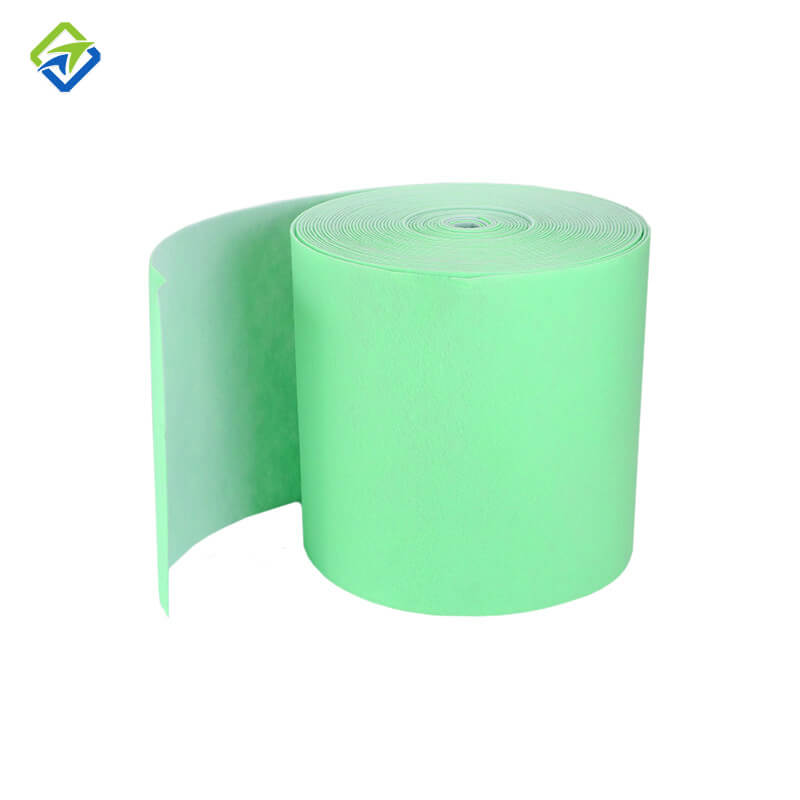

2. Synthetic Fiber Filter Cotton (The Future of Filtration)

Synthetic fiber is an emerging high-performance material widely considered the future direction of filtration technology. It is designed to replace traditional materials in many general filtration environments.

Key Features: Can fully replace non-woven and glass fiber products in primary, medium, and high-efficiency series.

Advantages: Lower air resistance, lightweight design, large dust holding capacity, and environmentally friendly.

3. Activated Carbon Filter Cotton (Odor Specialist)

Activated carbon filter cotton consists of synthetic fibers that have been impregnated with carbon and adhesive. Unlike other filters that focus on particle capture, its primary function is chemical adsorption.

Key Features: Excellent at removing odors and VOCs (Volatile Organic Compounds).

Usage Note: It does not emphasize particulate filtration efficiency. Therefore, it must generally be used in conjunction with other primary or medium-efficiency particle filters to be effective.

4. Fiberglass Filter Cotton (High Temperature & Paint Arrestor)

Fiberglass filter media is engineered from glass fibers of varying thicknesses and lengths using special processing techniques. It is the heavy-duty champion for specific industrial environments.

Key Features: Extremely stable performance, high-temperature resistance, high efficiency, and large capacity.

Applications: Widely used in general ventilation systems (primary to high efficiency) and critical for high-temperature filters.

The Spray Booth Standard: In specific environments like spray paint booths, glass fiber is often the only material capable of capturing paint mist (paint arrestors) effectively while maintaining airflow.

Summary: Which Filter Should You Choose?

| Filter Type | Best For | Key Benefit |

| Non-woven Filter Cotton | General HVAC, Pre-filters | Cost-effective & Durable |

| Synthetic Fiber Filter Cotton | Modern HVAC, Eco-friendly projects | Low Resistance & Green |

| Activated Carbon Filter Cotton | Commercial spaces, Kitchens | Odor Removal |

| Fiberglass Filter Cotton | Spray booths, High-temp areas | Paint Arrestance & Heat Resistance |

Explore our full range of air filters and find the perfect solution for your needs. If you need assistance purchasing filters or confirming filter size, please call +1 929-204-8922 (9-5 EST Monday-Friday) or email info@gdhaibei.com.